Quality Control

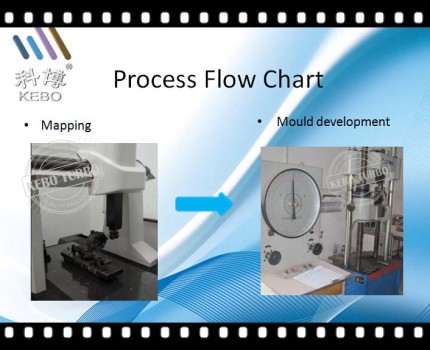

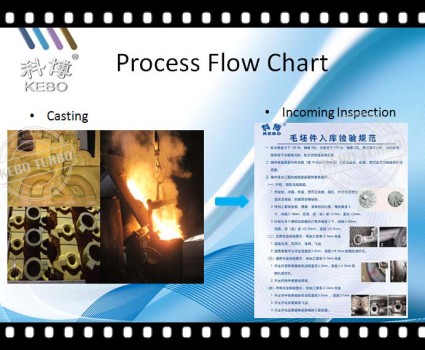

KEBO founded in 1995 as an outsourced machinery factory, and began to make turbochargers since 2000. It is commited to provide high quality, value service to its customers. It has implemented ISO/TS 16949 quality management system since 2010, and takes control of every single steps of production from mapping, molding, raw material control to final assembly.

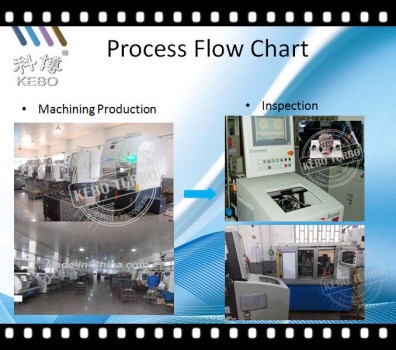

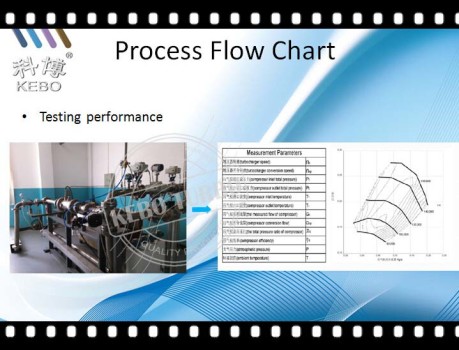

KEBO has an area of 16,000 square meters production floor, and more than 30 engineers & advanced technicians, equipped with full set production line and advanced processing & testing equipments, such as metallic processing machines, high precision digital controlled lathes, digital controlled grinding machines and overall digital honing lathes, automatic impeller balancer, dynamic balance testing machines and overall testing bench etc.

Every turbocharger we delivered, its turbine wheel & shaft, compressor wheel, rotor shaft, and its cartirdge have been properly balanced at first class balancing machines.